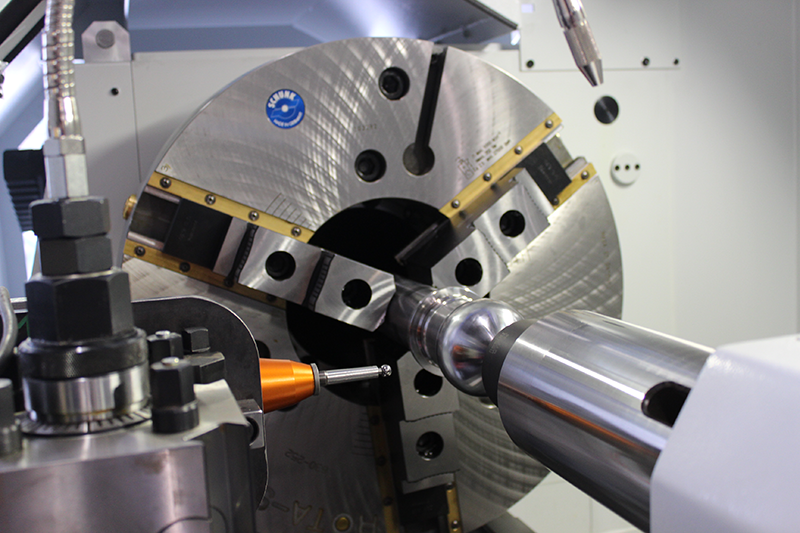

Machine Hammer Peening (MHP) always makes the workpiece better!

Any tool or equipment component where operating performance and life cycle improvement is desired, are candidates for peening. This includes parts subject to abrasion, wear, fatigue caused by thermal variances, fluctuating dynamic loads, stress cracking, environmental conditions, chemical corrosion, etc.

Different materials and objectives require adaptation of process parameters. These include hit rate, impact force, striker diameter & form, stroke length, pitch, feedrate, approach angle, etc. Our knowledge and experience allows us to assist you in setting up successfully for a wide range of applications.

Proven results include:

Reduced friction and better material flows from improved tribological effects of sliding surfaces in contact.

Applications

Industries

Automotive

Aerospace

Oil & Gas

Petrochemical

Wind Energy

Nuclear Energy

Mining

Railway

Transportation

Forestry

Defense

Marine

Ship-building

Agriculture

Construction

Food Processing

Plastics

Medical

Recreation & Leisure